Adidas MakerLab Reinvents Shoe Design With Campus 80

Adidas MakerLab reinvents how shoes are designed, made and sold with Campus 80.

Deconstruction was the theme for the Adidas Campus 80. From shoe design to manufacturing and how we purchase shoes. A blind bid through Stock X.

There’s a firm guardrail in place for the process of design, manufacturing and retailing for global businesses. Emerging brands, retailers and platforms are budding with new ideas on how to sell a vintage Hermes Kelly bag, all the way down to an oddly shaped vegetable. And then there’s Adidas, pushing innovation by gathering a global community of creators and craftsmen in their MakerLab. First created as space for Adidas designers to break away from their computers to feel the tactility of their process; MakerLab soon opened its doors as a design lab for consumers for events and have now become a lab for open-source creativity. With experimentation, roadblocks in the process are inevitable. What becomes a muscle memory down the assembly line of manufacturing is unraveled when creators challenge each step and toy with new ideas. The willingness to reinvent takes a village mentality for the entire system from a sketch of a designer to the moment it goes on your feet.

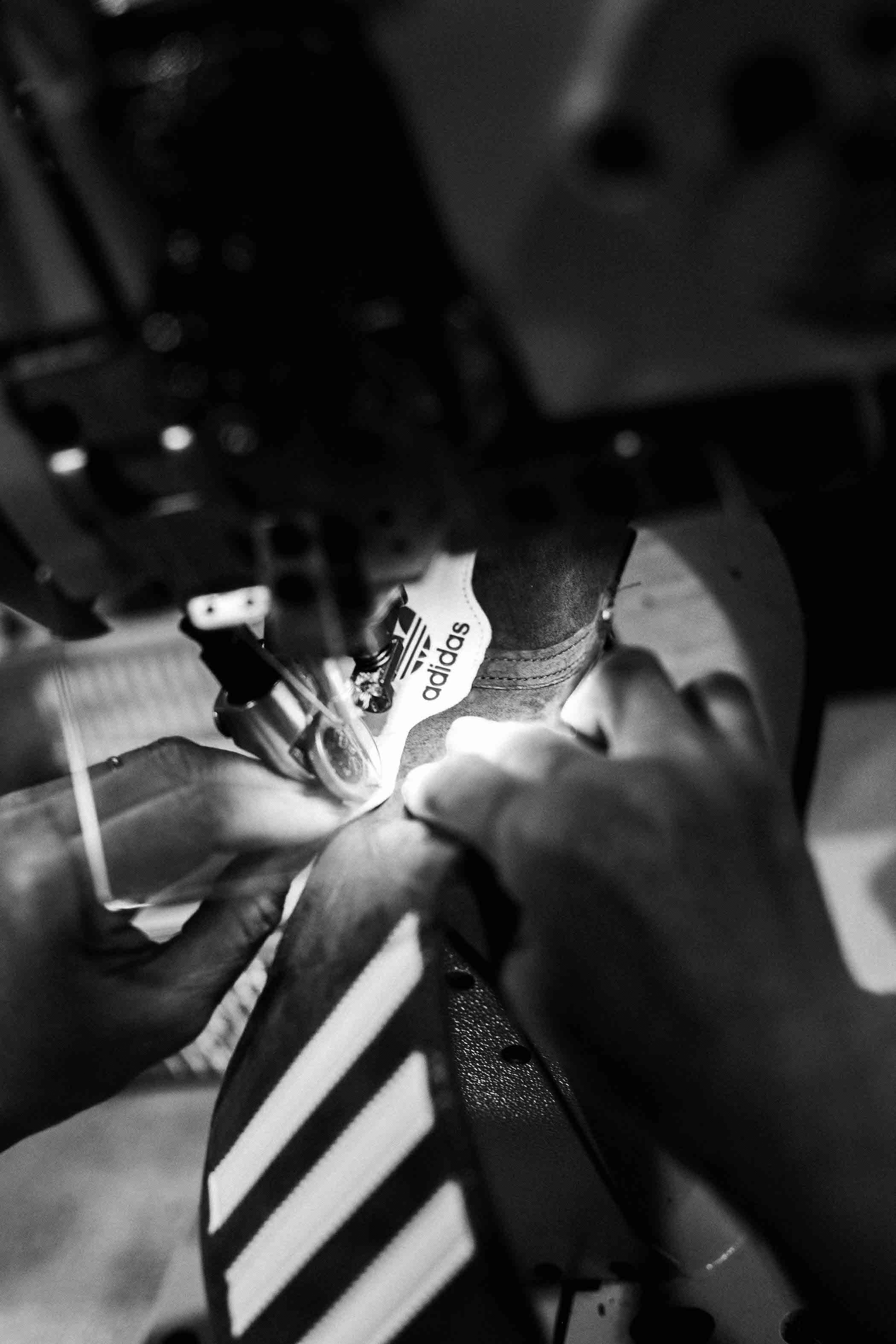

Imagine getting a call from Adidas, asking you to sort your life in ten days and prepare to spend 12 weeks in Germany at their MakerLab. Three designers with very different backgrounds were chosen to reimagine the classic Campus 80. Each designer has an intimate relationship with reconstructing shoes that dictates their process and solution. Slight tweaks on the tongue, overlapping materials where they usually don’t belong. an addition to elastic, frayed edges that expose the life of a shoe before it’s wrapped in tissue and encased in the box—a human touch that echoes stitch-and-collage lifestyles. Sneaker collagist, Helen Kirkum from Northhampton has a more formal education in shoe design describes, “Everything is inspired by the process. When I deconstruct the shoe, I take the stripes off, the remnants of the thread are left. This is the reinforcement fabric. When you take the eyelet panel off, the reinforcement is on the other side. It’s really about exposing all those elements that you don’t usually see within the shoe. Same with this back panel. This is, in the factory, how you mark the middle of the toe. Exposing those elements that are really about process and making them into a feature. In my personal work, that’s what I do all the time.”

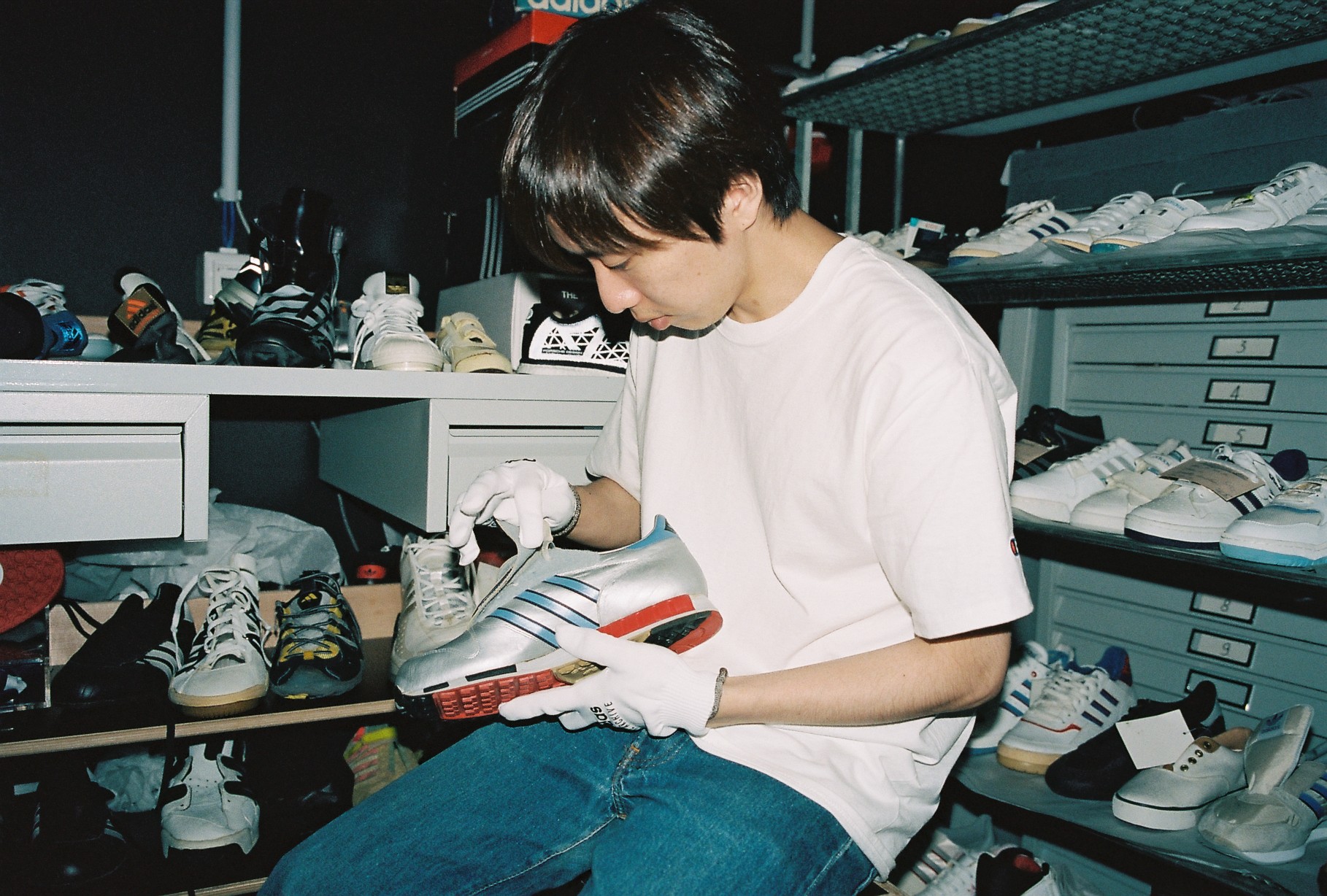

Shun Hirose has been repairing and restoring shoes for 13 years and only recently started custom shoe design 3 years ago. Because of his background as a cobbler over the years, he’s built an innate ability to understand the needs, wants and expectations of the person wearing the shoe. Known for his boot soles and sneaker uppers from Japan, Shun Hirose’s process was formed by his experience as a shoe cobbler. Shun went as far as arriving at the MakerLab with a shoe designed with a zip-up upper and boot sole which didn’t qualify for the end product. All assumptions, beliefs, and ideas had to be abandoned upon arrival.

Alex Nash who has a background in skate culture and customization dating back to 2003 also developed an attachment to the moccasin stitch that became his signature which he learned to let go of as his ideas expanded. “When I mastered my moccasin stitch I started elevating my other styles. You can’t just go on with a mocassin stitch with every custom I was doing, I was adding new elements and that’s how I began to make a name for myself.” And although the designers were given carte blanche to redesign the Campus 80, it’s a tricky dance to challenge brand guidelines and push the boundaries. Alex Nash tells us, “They have set rules. You can’t flip the logo upside down. You can’t mix hybrids together. You can’t sole swap shoes. I had the freedom to do what I wanted (with my own customization) I didn’t have to follow the rules. I could do whatever I want. I wanted shoes to look manufactured but was unique to me.”

The open-source design concept was stretched all the way out to the sale of each design. The end-user, (us) places a blind dollar value behind each shoe they are willing to bid for on Stock X. Stock X IPO is a blind auction designed to give the consumer control on placing value of the product. Create a Stock X account, select one of the three designs, place a bid for that shoe and by tonight, the lowest of the top ten bids will be the price all top ten bidders will pay for that shoe which is called the ‘Clearing Price’. So if you bid $1000 for a shoe and the Clearing Price is $200, then you win the shoe for $200.

“The blind bid format will be an analysis of how the end-user (you) will bid for these shoes blindly. There’s is no reference point to who is on the top ten to fully guarantee the shoe. Eliminating hype and potentially the adrenaline rush of bidding which sometimes can inflate the value of anything. In this case—sneakers.”

But in the three days the shoes went up on Stock X, the Adidas MakerLab Campus 80 IPO garnered nearly 10,000 combined bids with close to 7,000 participating bidders. The average clearing prices for each Campus 80 model were $198, $202, and $216, making the average overall clearing price $205. Which makes us wonder. If the bids were live, would that have driven the stock value of the shoe? When I sat down with the designers I asked how much their shoes would bid for. A modest pause was followed by a few nods as they unanimously exclaimed “priceless.”